2021 Good Quality Implant Surgical Packs - Surgical Ophthalmic Pack – JPS Medical

2021 Good Quality Implant Surgical Packs - Surgical Ophthalmic Pack – JPS Medical Detail:

Features and benefits

Components & Details

Code: SOP001

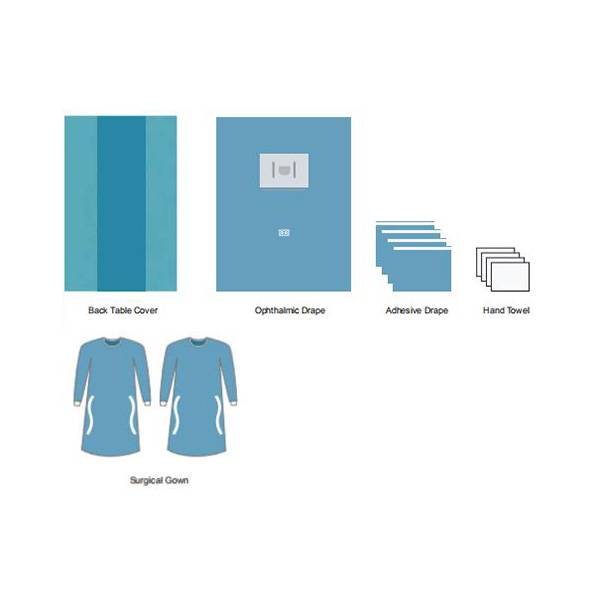

| NO. | Item | Quantity | |

| 1 | Back Table Cover 150x190cm | 1pc | 1 piece |

| 2 | Mayo stand cover 80*140cm | 2pcs | 2 pieces |

| 3 | Hand Towel 30x40cm | 4pcs | 1 piece |

| 4 | Adhesive drape 38x66cm | 4pcs | 1 piece |

| 5 | Ophthalmic drape 134x178cm | 1pc | 1 piece |

What are the benefits for disposable surgical ophthalmic packs?

The first is safety and sterilization. The sterilization of the disposable surgical ophothalmic pack is no longer left up to the doctors or the medical staff but rather is not needed as the surgical pack is one time use and is disposed of afterwards. This means that as long as the disposable surgical pack is used once, there is no chance of cross contamination or of spreading any diseases with the use of the disposable pack. There is no need to keep these disposable packs around after use in order to sterilize them.

Another benefit is that these disposable surgical packs are less expensive than traditional reused surgical pack. This means that more attention can be paid to things like taking care of patients rather than keeping up with expensive reusable surgical packs. Since they are less expensive they are also not as big of a loss if they are broken or lost before they are used.

Product detail pictures:

Related Product Guide:

The crawler turner adopts the crawler drive design, which can be operated by one person. When it works, the crawler straddles the strip compost pile, and the cutter shaft at the lower end of the frame rotates to mix and turn the raw materials. The operation can be done not only in the open air area, but also in the workshop or greenhouse. 2021 Good Quality Implant Surgical Packs - Surgical Ophthalmic Pack – JPS Medical , The product will supply to all over the world, such as: venezuela, Barcelona, Mecca, Organic fertilizers can be divided into powder and granular organic fertilizers according to their forms. The production of granular organic fertilizers requires a granulator. Common organic fertilizer granulation equipment on the market: roller extrusion granulator, organic fertilizer stirring tooth granulator, drum granulator, disc granulator, compound fertilizer granulator, buffer granulator, Different granulators such as flat die extrusion granulator, twin screw extrusion granulator, etc.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.